Skip to content

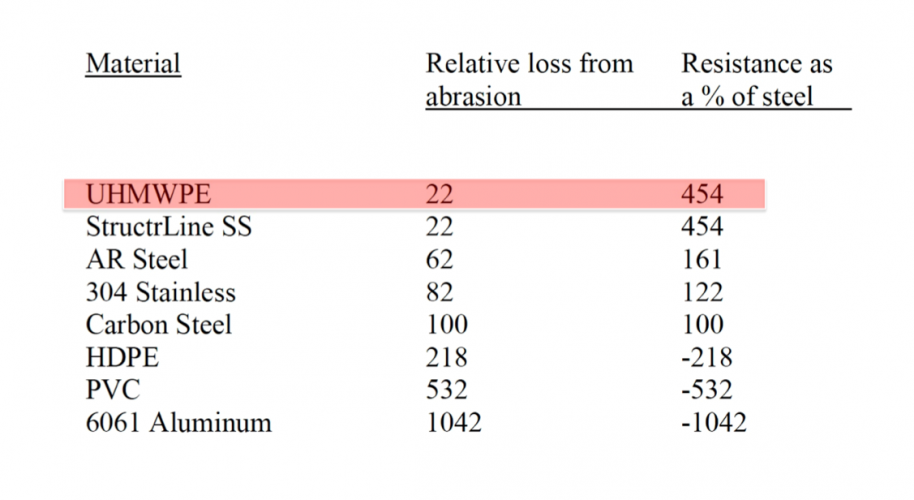

Abrasion Resistance

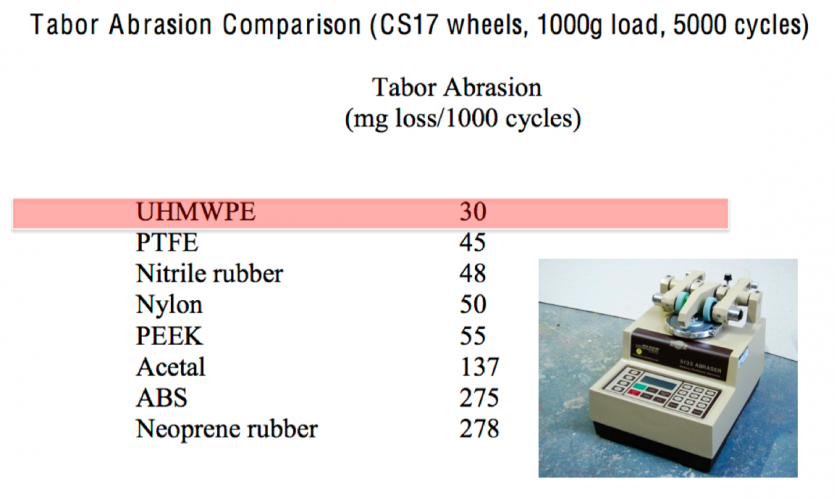

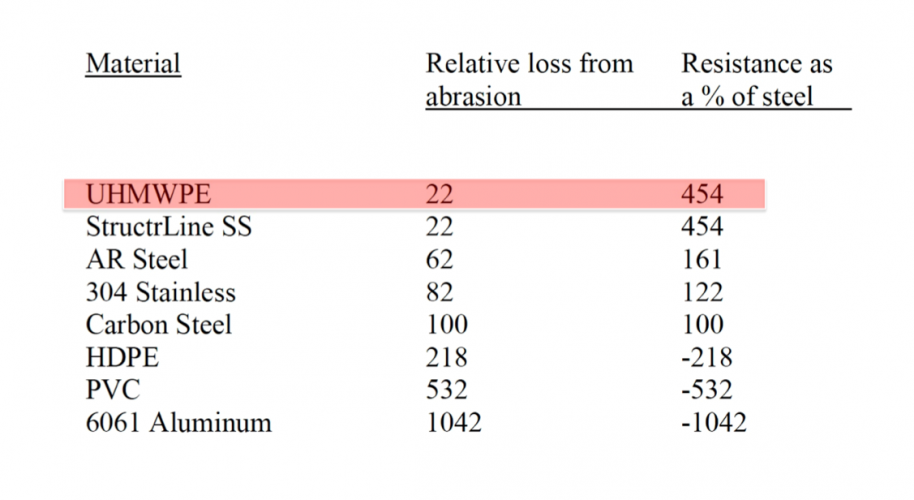

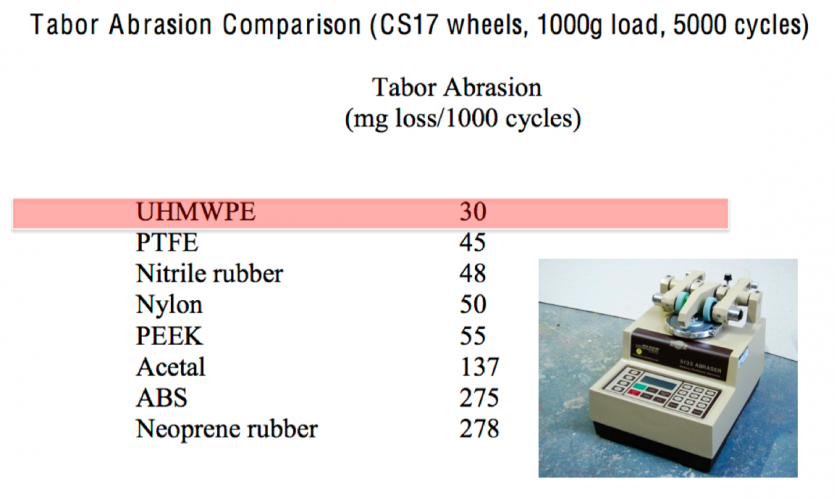

- Of all the pipe materials, UHMWPE pipes exhibit the smallest abrasion index. Of all the plastic pipes presently available, the anti-abrasion performance of UHMWPE is 18 times higher than phenolic polymers, 6 times higher than polyamide polymers (PA66), 5 times higher than poly(tetrafluoroethylene) (PTFE) as well as being 6.6 times higher than carbon steel, 5.5 times higher than stainless steel and 27 times higher than copper, so Ultra™ UHMWPE pipes can profoundly increase the service lifespan of slurry pipes.

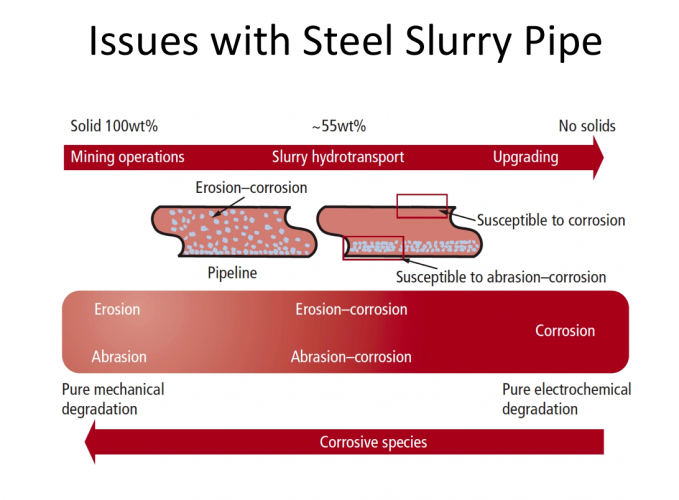

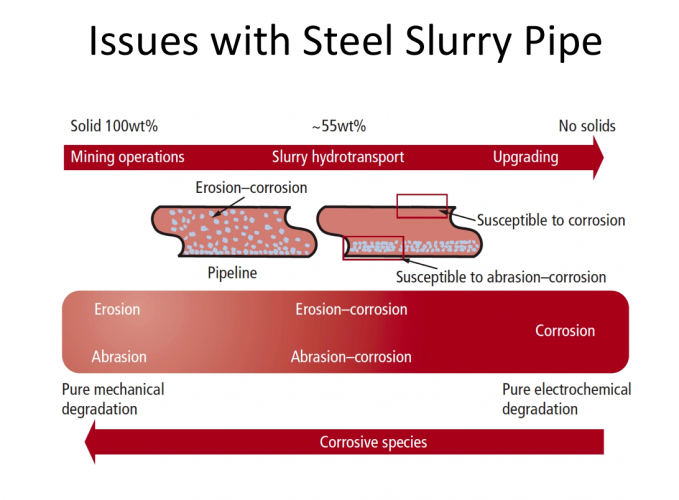

Advantages of UHMWPE Over Steel Pipes

- When abrasive materials are transported through steel pipe their effect on the inner pipe surface can be very damaging. Abrasive wear within these transportation systems occurs when hard particles are forced against or slide along the wall of the pipe. A loss of wall thickness is the result of the hard, sharp, angular edges producing a cutting or shearing action on the pipe wall. In more extreme cases, these effects can result in pipe leaks or failure, or significant maintenance costs and downtime for pipe replacement. Mild steel pipe is simply not abrasion resistant enough to stand up to the abuse for more than a year or two.��Most abrasion-resistant pipe options operate on the premise that when two objects meet, the harder object’ wins’. To deal with this phenomenon, products are available in a variety of hardnesses, measured on the Brinell Scale, from A-R steel (200 BHN) through iron cast pipe (up to 800 BHN). Unfortunately, any product that is very hard throughout the wall thickness is also extremely brittle. Excessive brittleness is unacceptable, as piping systems are constantly flexing and moving as a result of pressure surges and spikes and due to mechanical and physical contact at a plant.��However, one type of pipe can offer the best of both worlds: recently developed UHMWPE pipe exhibits extremely high abrasion resistance combined with good ductility and flexibility. Ultra PE Pipe will typically last two to four times as long as mild steel in high-wear slurry applications. ��The pipe can be cut and bent like regular polyethylene pipe and accepts standard end options of flanges, weld rings, and couplings.

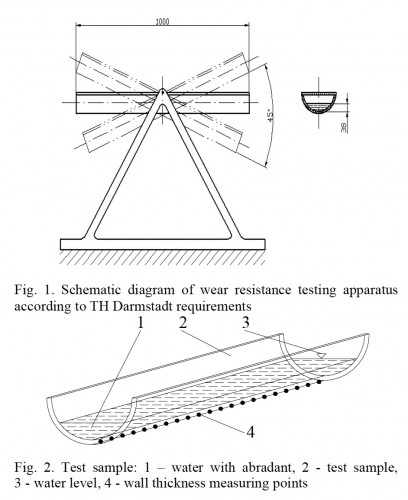

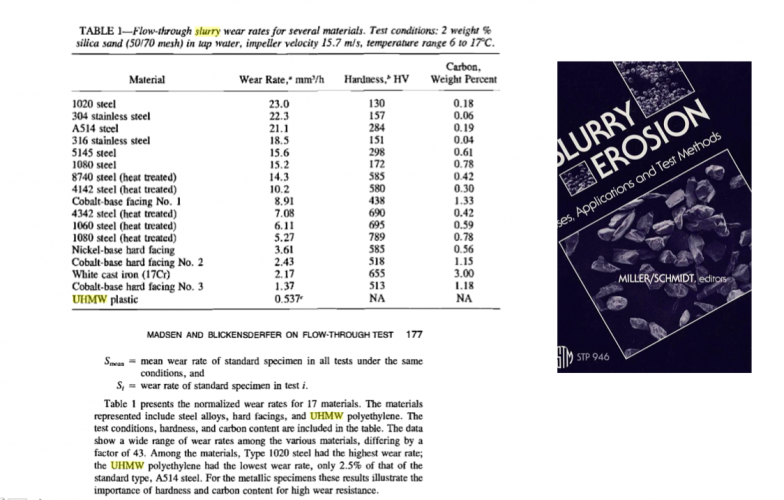

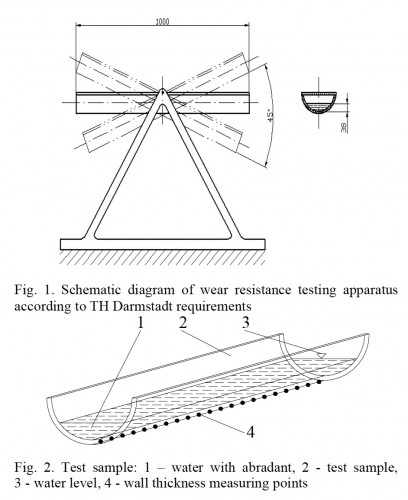

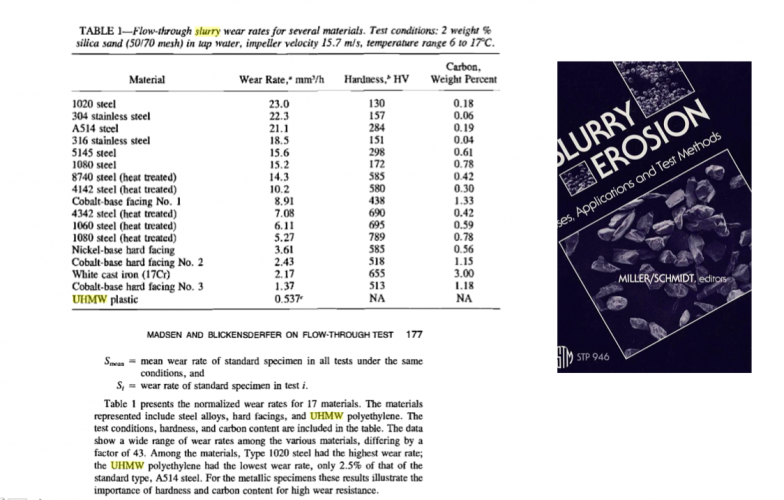

Slurry Wear Resistance

Wear Resistance Table

Taber Abrasion Resistance